Oil and grease resistance is an essential property for materials used in packaging, textiles, and industrial applications. Whether it’s food containers, workwear, or automotive parts, the ability to repel or resist oils and grease helps maintain product integrity, hygiene, and durability. To ensure products meet the required standards, various test methods are used to evaluate oil and grease resistance. In this blog, we will explore the most common testing methods, their procedures, and their significance.

Why Test for Oil and Grease Resistance?

Materials exposed to oils and greases can degrade over time, leading to:

- Staining and Discoloration: Especially in textiles and paper products.

- Structural Weakening: In packaging, this can compromise the product’s protective function.

- Hygiene Concerns: Particularly in food packaging, where grease penetration can lead to contamination.

Testing for oil and grease resistance ensures that products maintain their performance and appearance, meeting industry standards and consumer expectations.

1. Grease Resistance Test for Paper and Paperboard (TAPPI T559 cm-12). This method is also known as the 3M Kit test.

Purpose: To determine the resistance of paper and board to oils and greases.

Procedure:

- A series of standardized solutions with varying surface tension are applied to the test sample.

- The solutions are left on the material for a specified period.

- The highest numbered solution that does not penetrate or cause visible staining on the other side of the material determines the kit rating.

Applications: Commonly used for food packaging materials like paper plates, wrappers, and containers.

2. Oil Repellency Test (AATCC 118)

Purpose: To measure the resistance of fabrics to oil penetration.

Procedure:

- Drops of standardized oil solutions are applied to the fabric.

- The repellency rating is determined by the highest numbered solution that does not wet the fabric surface.

Applications: Used in the textile industry for workwear, upholstery, and outdoor gear.

3. Gravimetric Analysis

Purpose: To measure the amount of oil and grease absorbed by a material.

Procedure:

- The sample is weighed before and after exposure to oil or grease.

- The difference in weight indicates the amount of oil absorbed.

Applications: Useful for evaluating the performance of absorbent materials like wipes and filters.

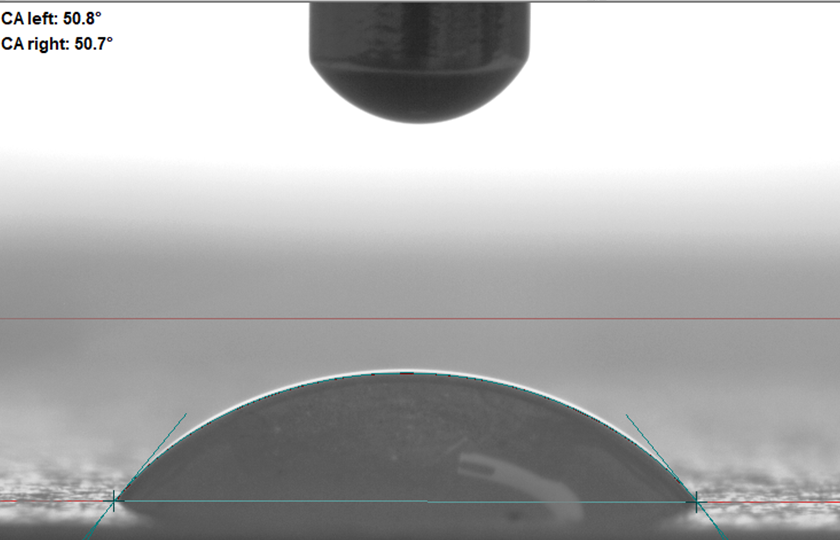

4. Contact Angle Measurement

Purpose: To determine the wettability of a material’s surface by oil or grease.

Procedure:

- A droplet of oil is placed on the material’s surface.

- The contact angle is measured.

- A higher contact angle indicates better oil repellency.

- Non-wetting = 180°

- Poor wetting > 90°

- High wetting <90°

- Complete wetting = 0°

Applications: Used in evaluating coatings and surface treatments for oil resistance.

Factors Influencing Oil and Grease Resistance

Several factors can affect the results of these tests, including:

- Material Composition: The type of fibers, coatings, or additives used.

- Surface Treatment: Hydrophobic or oleophobic treatments can enhance resistance.

- Temperature and Humidity: Environmental conditions during testing can influence performance.

- Type of Oil or Grease: Different oils (e.g., vegetable vs. mineral) have varying viscosities and penetration properties.

Trust SNP Inc. To Ensure Your Products Are Tested Properly

Testing for oil and grease resistance is crucial for maintaining product quality, performance, and safety. By using standardized test methods, manufacturers can ensure their products meet industry standards and consumer expectations. Whether it’s for food packaging, textiles, or industrial applications, understanding these tests helps in selecting the right materials and coatings to enhance product durability and functionality.

Interested in improving the oil and grease resistance of your products? Contact us today for more information on advanced coatings and treatments or to schedule a consultation for product testing!